Introduction

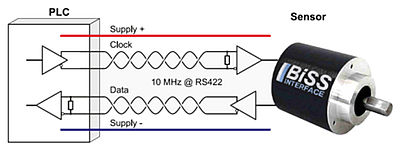

BiSS is an open source digital interface for sensors and actuators.

The interface features high-speed bidirectional communication, and is implemented on simple hardware (compatible with industry standard SSI). It is suitable for real-time data acquisition and provides safety features like CRC protected transmission.

History

For a long time position encoder manufacturers have relied only on analog signal transmissions or simple digital incremental signal transmissions in order to provide position information. As encoder technology evolved, new techniques and higher level integration were possible, enabling encoders to generate high resolution absolute data position, with additional features like commands, register communication, etc. Thus it was necessary to implement a new interface, with characteristics suitable for these higher-end devices. SSI is an outdated industry standard and does not provide the speed or the additional features required by the manufacturers. Some manufacturers released their own proprietary interfaces, which were exclusive to their own products and not compatible between each other.

The BiSS interface was introduced by iC-Haus as an open-source interface in 2002. iC-Haus wanted to achieve a fast bidirectional sensor/actuator communication standard that remained compatible with the established SSI (Synchronous Serial Interface) standard. Throughout more than 20 years, BiSS adoption has increased constantly, with currently over 650 licensed device manufacturers, including industry leaders like Balluff, Baumer, Danaher Motion, Kübler, Hengstler, Hohner, Pepperl+Fuchs, Renishaw, Schneider Electric, Yaskawa, Yuheng Optics, and many others.

Features and Advantages

BiSS interface is a dedicated, real-time sensor/actuator interface as opposed to a general-purpose field bus. The main features of the BiSS interface are listed below:

- Open source

Unlike many proprietary interfaces in the market, BiSS is completely open source. This enables different manufacturers to create products with the same interface, increasing compatibility between different vendors. This is an advantage not only for the manufacturer that has direct access to a full featured and high quality interface, but also for the consumer who does not stay limited to the product and price monopoly of one manufacturer. - Fast serial synchronous communication using two unidirectional signals

BiSS is a serial interface which reaches high speed transmissions, usually up to 10 MHz over long lines using standard RS422 transceivers or up to 100 MHz along short distances with LVDS connections. - Bidirectional

BiSS offers permanent bidirectional mode (continuous operation, no mode change necessary) with BiSS-C allowing also both sensor and actuator communication on the same channel using only two additional lines. - Line delay compensation

Industrial applications require the communication to work reliably even through long cables in noisy environments. BiSS interface is suitable for such applications, offering compensation of line delays and thus achieving high speeds even over long distances. - Safety features

The BiSS interface fulfills safety application demands, offering additional errors and warning messages from the sensor to the controller and up to 16-bits CRC protection for the transmitted data. - Bus capability

Some applications require synchronized data acquisition of multiple sensors, for example: multi-axis motion control. BiSS interface offers bus capability, reducing considerably the complexity of the controller by connecting all the sensors in a chain, linked to one data channel at the controller. - Device description

The BiSS interface provides an electronic identification of a device, making easy Plug-and-Play connection possible. Through the use of standardized descriptions inside EDS (Electronic DataSheet, information written inside the device's memory), XML files or standard BiSS Profiles, all the parameters of the device can be loaded directly by the controller, which can adapt its own settings to the connected device. BiSS licensed manufacturers receive a unique Manufacturer ID, allowing them to identify its own products in the market.

The BiSS protocol frame is represented by the diagram below:

In the BiSS communication, the controller requesting the data (controlling the operation) is called the BiSS Master, while the sensor providing the acquired data is the BiSS Slave (an actuator is also considered a slave receiving data from a BiSS Master).

Implementation

The implementation of a BiSS communication system is simple and is achieved with minimum hardware requirements.

Due to its low resource requirements, the BiSS slave is usually implemented directly inside the sensor IC. Approximately 1,000 gates are used to implement a BiSS slave, making it practical to be integrated inside the sensor IC, and therefore eliminating the requirement for additional space at the PCB for protocol data processing, as is usual with general-purpose field bus interfaces.

The BiSS Master can be implemented through different solutions, according to the manufacturer's requirements and expertise:

- BiSS master iC

iC-Haus offers the iC-MB4 integrated circuit, which contains the complete functionality of the BiSS protocol. The iCs can be controlled using a microcontroller parallel or serial interface. - FPGA based BiSS master

Different VHDL IP Cores are available containing the BiSS master functionality, and can be included in the manufacturer's FPGA or CPLD hardware. - Microprocessor based BiSS master

A BiSS master can be implemented using a DSP/MCU/CPU unit.

In order to ease the implementation and testing of the BiSS interface, many tools are available, including BiSS-to-USB adapters (with BiSS Reader software), Logic Analyzer with BiSS protocol interpretation, VHDL simulation blocks, etc.

BiSS Safety

BiSS Safety follows the industrial trend of fully digital communication and functional safety capabilities. Safety-critical applications targeting up to SIL3 can now be fully covered by BiSS Safety and the BiSS interface. BiSS Safety uses the BiSS protocol-specific features of the BiSS bus structure and the CRC cyclic redundancy check for a safe "Black Channel" transmission.

The safety communication level "BiSS Safety" is certified by TÜV Rheinland and follows in extracts the requirements stated in DIN EN 61784-3:2011 and can be used in safety applications up to SIL3 according IEC61508:2010.

The BiSS Safety standard is 100% compatible with BiSS-C: physical layer, transmission medium and communication protocol are not modified from existing BiSS-C systems. The slave (encoder) must generate and transmit two position values (CPW: Control Position Word and SPW: Safety Position Word), and the master must check them against each other to certify the data validity. Additionally, longer CRC data and a sign-of-life counter value must be sent to increase the error detection capabilities, therefore achieving the necessary error detection level for a safety-compliant system.

BiSS Line

BiSS Line follows the industrial trend of fully digital communication, functional safety capabilities and motor power supply over a single cable. However, BiSS Line provides all specific features of BiSS-C. The data transmission is based on the industrial standard RS-485 and is protected by forward error correction (FEC) against disturbances coupled from the motor line to the data line.

There are already one-cable solutions in the market, but all of them are proprietary, and thus cannot be adopted by interested parties. BiSS Line is an open standard, and can be implemented as a 2-wire configuration (data transmission combined wih energy transmission) or a 4-wire configuration (separate energy transmission). The connection technology, as well as suitable cables, are already available.

License

The BiSS interface is developed by iC-Haus GmbH, which holds the patent for this protocol. While the process and designs of BiSS C are patented by iC-Haus GmbH, they are still part of the free BiSS license and available to all BiSS Device Manufacturers. Interested manufacturers can apply for a free of charge license, thus having access to the IP Cores source codes, as well as the free use of the BiSS logo and trademark.

For more information regarding the BiSS protocol licensing model, please refer to the link at the end of this page.

Certification

With its global distribution, the demands for ensuring compatibility between different BiSS devices have grown. There is a set of features and functionality that are mandatory for successful certification. We can provide a certification service through one of our members.

After successful testing, devices are granted as BiSS certified. A report file including measurement details and diagrams is provided confidentially to the device manufacturer in order to document the certification procedure, indicate discrepancies, and support improvement. The certificate lists all features and functions including data channel and timing parameters that have been verified and approved during certification. It summarizes all relevant BiSS parameters that are required by a BiSS master to enable proper communication.

Related links